Neal R. Armstrong looked at the monitor in his solar energy lab and jumped. “That’s a good looking I-V curve!” he exclaimed.

An I-V curve is a graph relating current and voltage. The ideal I-V curve is a rectangle, but that’s not possible in reality, so to see the curve make any sort of sharp turn is incredible.

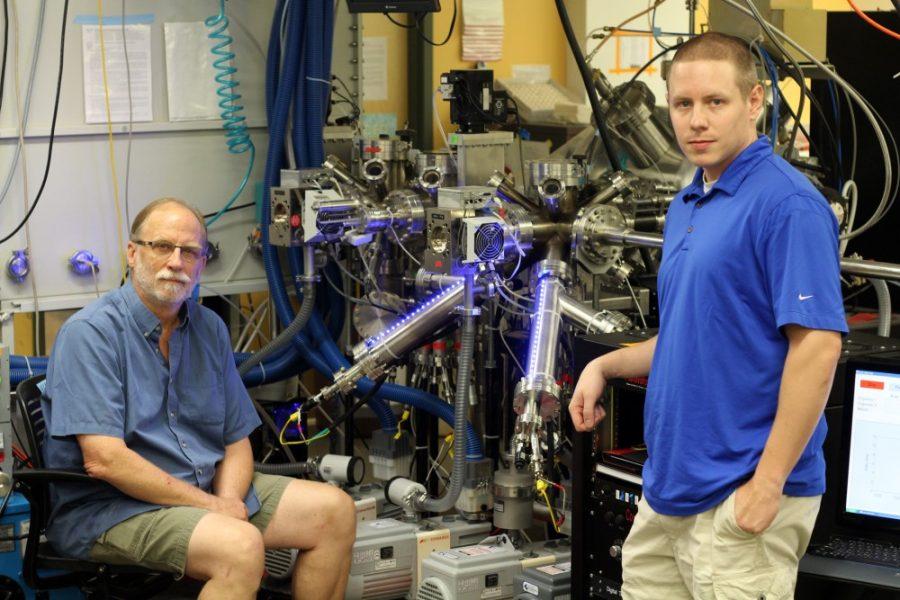

Armstrong, a Regents’ professor in optical sciences and director of the Center for Interface Science: Solar Electric Materials (CIS:SEM), has been working with his lab on a way to make solar energy more efficient, and the sharp turn he saw indicated another promising result for the series he was working on.

“Dr. Armstrong was surprised that the shape of the I-V curve was good, which is not something that we’ve been seeing in that kind of material before … but it is a good thing,” said Kai-Lin Ou, a graduate student who has been working on this project for five years and was taking the data that elicited Armstrong’s energetic response.

As Tucson has an average 193 days of clear skies a year, it’s only natural for residents to look toward solar energy as a viable renewable resource. Unfortunately, solar energy is much too expensive to sustain long-term growth.

Armstrong is looking to change that.

“This is an example from a colleague of mine in Denmark,” Armstrong said, holding up a transparent sheet of plastic with beige polygons sliced by opalescent black lines. “This is a printed solar cell. What you’re looking at started out as a transparent piece of plastic … It was part of a massive roll a hundred meters in length.”

The components of this solar cell were printed onto a sheet of plastic, similar to how newspapers are mass-produced. This process is cheap, but the final product is not efficient enough to replace the current industry standard, a silicon wafer attached to electrodes and suspended in glass, the device most people picture when they think of solar power.

CIS:SEM is looking for ways to make these cheap, printable solar cells a commercial possibility. At institutions across the U.S. — including the UA, the Georgia Institute of Technology, and Princeton University — CIS:SEM is redesigning the pieces of this photovoltaic cell.

The purpose of CIS:SEM is simple: “I think the ultimate goal for the overall solar cell field is to have high-efficiency, reliable devices,” Kai-Lin said.

CIS:SEM’s research revolves around the few nanometers in contact with the lit surface, a conductive layer used to draw the captured energy from the absorbing ink.

“For our lab, we are focusing on basic science,” Kai-Lin said. “It’s not that we are pursuing the highest efficiency … It’s fundamental, basic science that we’re working with right now.”

The need for affordable solar solutions is at an all-time high. As power companies achieve the mandated goal of renewable energy resources, incentives are disappearing for those wishing to install solar panels on their homes or buy power from solar fields. This means solar power is an unreasonable option for most Arizona homes, at least until it becomes more affordable.

Despite all the uncertainty about the future of sustainable energy, Kai-Lin is still optimistic.

“I think that we are actually starting a new generation of solar cells at this point in time,” he said. “[We’re working with] a completely new type of material. There are a lot of people focusing on this. I think the future of the solar cell is very bright.”