Chances are you’ve seen Arizona Stadium before. You might have even watched a football game or two while cheering from the student section. But did you know that underneath the east wing of the stadium lies one of the world’s preeminent manufacturers of cutting edge telescope mirrors?

The Richard F. Caris Mirror Lab is currently creating mirrors that are essential for the world’s best telescopes to function, including the under-construction Giant Magellan Telescope, which will be the biggest optical observatory ever built once it is completed.

“The reason for the mirror lab is so the astronomers at the UA can be partners in some of the most powerful telescopes in the world and so they’ll have access to them,” said Hubert Martin, project scientist at the Mirror Lab. “With that, they can do research most people around the world can’t do.”

In 1980, astronomer Roger Angel founded the lab after inventing a process that would allow him to produce very large telescope mirrors that would also be light in weight. In order to do this, he made mirrors that were mostly hollow, not solid, Martin said.

In 1997, the lab created its first 8.4-meter mirror for the Large Binocular Telescope. The lab would go on to create seven more of these giant mirrors for the present day’s cutting edge Giant Magellan Telescope, three of which are already completed with the fourth on its way.

RELATED: 11 graduate students receive recognition as Carson Scholars

The process of creating these large mirrors is all about detail.

“There are a lot of ironies in the Mirror Lab,” said Don McCarthy, an astronomer at the Steward Observatory. “For example, you’re building a giant mirror, but it has to be accurate to microscopic accuracy.”

According to Martin, there are two important reasons why the giant mirrors must be so lightweight.

First, the mirrors can’t be so heavy they bend under their own weight in the telescope.

Second, if the mirrors are heavy then the telescope structure will have to be massive in order to support them.

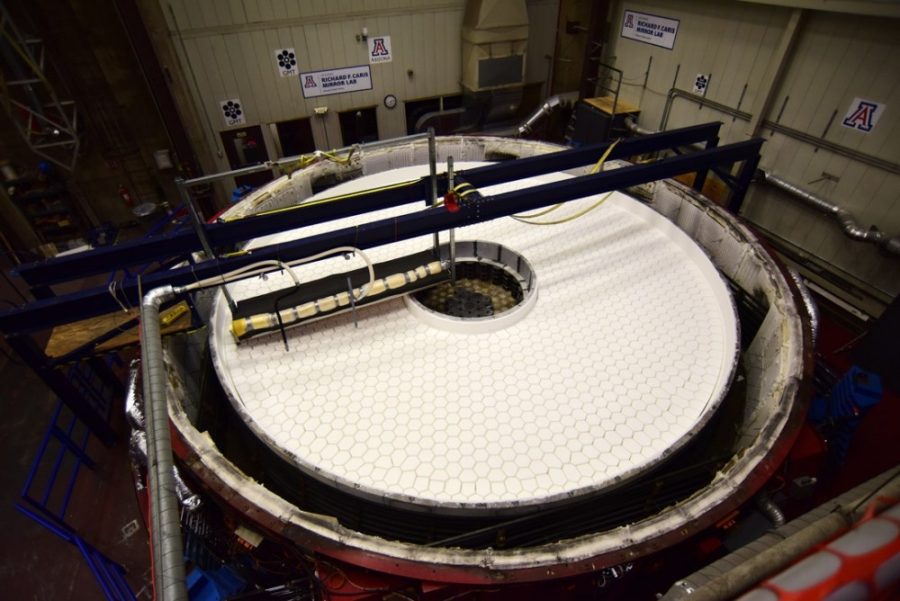

Martin said to begin building the mirrors, the scientists first must build a mold in a hexagonal shape, similar to that of a honeycomb. It’s this hexagonal shape, made up of 1,700 cells, that gives the mirrors their signature lightweight structure.

Next, the chunks of glass are placed on top of the mold and enclosed in a furnace, which is heated to 1,200 degrees Celsius.

The electric coil heaters in the walls, ceiling and floor heat the glass until it melts and begins to flow through the gaps between the boxes and into the mold, Martin added.

As the heated material fills the mold, a continuous layer of glass forms on the top and bottom.

Once the glass has finished cooling, the boxes are washed out from the middle of the mold, leaving a solid piece of glass with empty spaces where the boxes used to be.

According to Martin, even though it’s hollow, it’s still a very stiff structure because the entire mirror is nearly a meter thick.

This thick structure is essential in preventing the mirror from bending within the telescope on windy days and forming blurry images.

“These mirrors make it possible to do something that never could be done before, which is make a mirror that’s eight meters in diameter that will hold its shape very accurately in the telescope, so it can always form sharp images,” Martin said.

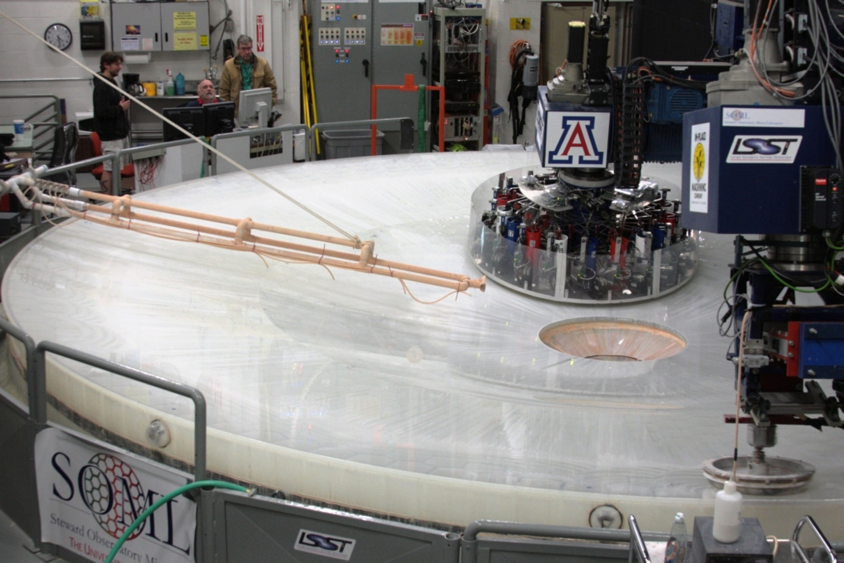

McCarthy said once the mirror is formed, it will spend the next few years of its life being polished. From start to finish, the building of these mirrors can take anywhere from four to six years to complete.

“The accuracy requirement is so tight you have to get down to an accuracy of about a millionth of an inch. That’s how smooth it must be to be the perfect surface, the perfect shape that would form a perfect image,” Martin said.

RELATED: UA students walk out in protest of President Trump’s climate change vision

But why do these mirrors need to be so massive?

According to Martin, the size of the mirror determines the size of the image you get from space.

If the mirror is large, then you’ll get a very sharp image which will allow you to learn more details about the object or location you’re studying.

Perhaps one of the best parts about the Mirror Lab is that it isn’t just for trained scientists and astronomers; students play an active role in it, too.

According to McCarthy, students with backgrounds ranging from engineering to public health have the opportunity to work at the lab.

Tours of the Mirror Lab are also available to the public.

Follow Hannah Dahl on Twitter.